I have a basic ro. 1 sediment filter. 1 carbon filter. ro membrane. small di canister that sits on the ro canister. the resincanisterholds 1/3 of a standard 10 in canister. I deplete the di resin in around 30 or 40 gallons. Is this normal?

What would the best set up as far as number and type of filters to use pre ro to deal with high chloramines? I'm assuming the chloramines are depleting the di faster than should be.

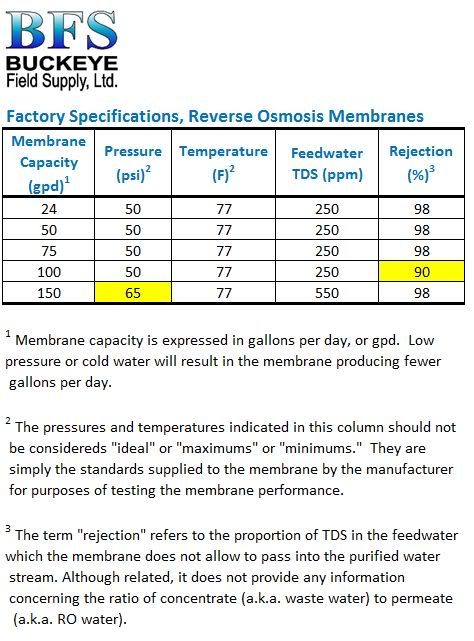

I was around 140 tds with tds of 0 after the di. Now I'm at 110 in and 50+ out. I'm assuming 2 things happened. One ... my di has run its course time to order some new. And 2 my ro has holes in the membrane? I heard a good running ro should reduce tds by around 80% is that correct?

Next question. With my ro working unefficiently could that be a cause of my cyano problem or would it be possibly old live sand?

Last. I have heard there are 3 types of ro membranes. Anyone know what they are and the diffrence between them?

What would the best set up as far as number and type of filters to use pre ro to deal with high chloramines? I'm assuming the chloramines are depleting the di faster than should be.

I was around 140 tds with tds of 0 after the di. Now I'm at 110 in and 50+ out. I'm assuming 2 things happened. One ... my di has run its course time to order some new. And 2 my ro has holes in the membrane? I heard a good running ro should reduce tds by around 80% is that correct?

Next question. With my ro working unefficiently could that be a cause of my cyano problem or would it be possibly old live sand?

Last. I have heard there are 3 types of ro membranes. Anyone know what they are and the diffrence between them?