A Golden Reef Tank (v2)

- Thread starter halmus

- Start date

This again is why this is probably the best build in Denver

I'm just a few weeks away from introducing the first fish. I could probably do that anytime but I don't want the added complications at this point. I haven't measured a single parameter the Apex hasn't given me. I'm still doing major water changes every week (125 gal) and the skimmer is still producing junk. All of the dead rock will be leaching out for a while.

So is everything online? It looks awesome. I can't believe the amount of planning and time you took to build all of this. I have two questions. 1. When do you want to host a meeting? 2. What happens if you turn the power off? I worry about one tank one sump. I'd like to do something similar on a much smaller scale and I

When do I want to host a meeting? My next step is to design and build the motor and control system that will move the hood in and out. Once that's done, I'll finish the cabinet work to close in the hood. I'd be happy to host a meeting then. I'm thinking that all of that should be complete by some time in January. Maybe we can plan on a February meeting here? There won't be much going on at all for coral or fish, but everyone can see the system early on.

What happens if you turn the power off? I've tested some combinations of various pumps failing. I've also tested a total power failure. The main sump does handle the overflow. Still, I want to make some adjustments so that so much doesn't back-siphon into the sump. For extended outages, I have a small generator. I designed the overflow section to be larger than really necessary. I can stick a heater or pair of heaters in the overflow and plug in one of the Vectras in the overflow to the generator. There is plenty of room in the overflow to work with. That will ensure the display stays up. I will probably look into battery backup for the Vortechs.

Thanks! I've seen a few other solutions for organizing Apex and wiring that I actually like better but if everything has to be surface mounted on a wall, this is a pretty clean solution.

. What are some of these systems for organizing you speak of?

. What are some of these systems for organizing you speak of?I saw one elegant solution somewhere but I don't know who to give the credit. This person mounted a big sheet of plywood (or wall?) that was exposed on the back side. They mounted the controller, power strips, other electronic boxes they desire to be exposed on the face of the plywood. They drilled access holes by data and power line hook up points. Then, they routed all of the cords in from the back with the excess cabling hanging behind out of sight.

This solution doesn't eliminate the birds nest of wires. It just hides the nest out of site. That's better than nothing. It's also a really clean looking solution from the front. Frankly, it looks better than what I did because you don't need these cable raceways in view. The best solution might be to incorporate both. Hide cords on the back well managed.

One thing I tried hard to do was keep data lines well separated from 120 VAC. This is common practice in the world I work in (radio communications). I believe it's also recommended by Apex but I didn't read the manual. That's why I have some larger tracks for the 120VAC and smaller tracks for CAT5, Apex data, and other low voltage lines. The recommendation is that if those lines have to cross each other, they do it at a 90 deg angle. I attempted the same in the overhead cable trays.

This solution doesn't eliminate the birds nest of wires. It just hides the nest out of site. That's better than nothing. It's also a really clean looking solution from the front. Frankly, it looks better than what I did because you don't need these cable raceways in view. The best solution might be to incorporate both. Hide cords on the back well managed.

One thing I tried hard to do was keep data lines well separated from 120 VAC. This is common practice in the world I work in (radio communications). I believe it's also recommended by Apex but I didn't read the manual. That's why I have some larger tracks for the 120VAC and smaller tracks for CAT5, Apex data, and other low voltage lines. The recommendation is that if those lines have to cross each other, they do it at a 90 deg angle. I attempted the same in the overhead cable trays.

Good job with all that. Seems like quite an undertaking.

-Kamran

-Kamran

I’ve enjoyed my build and am very proud of it, but this is spectacular. I have new aspirations!

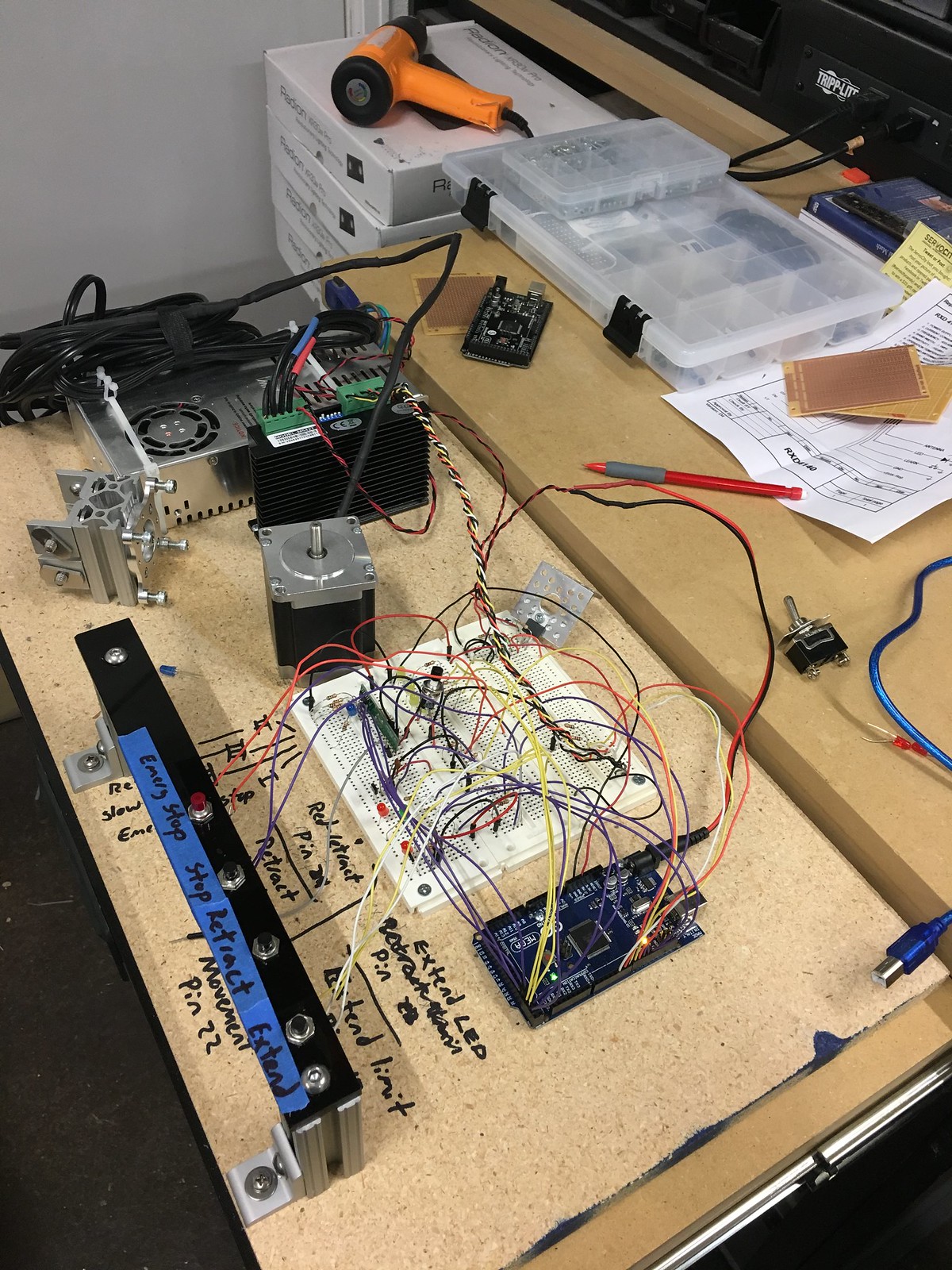

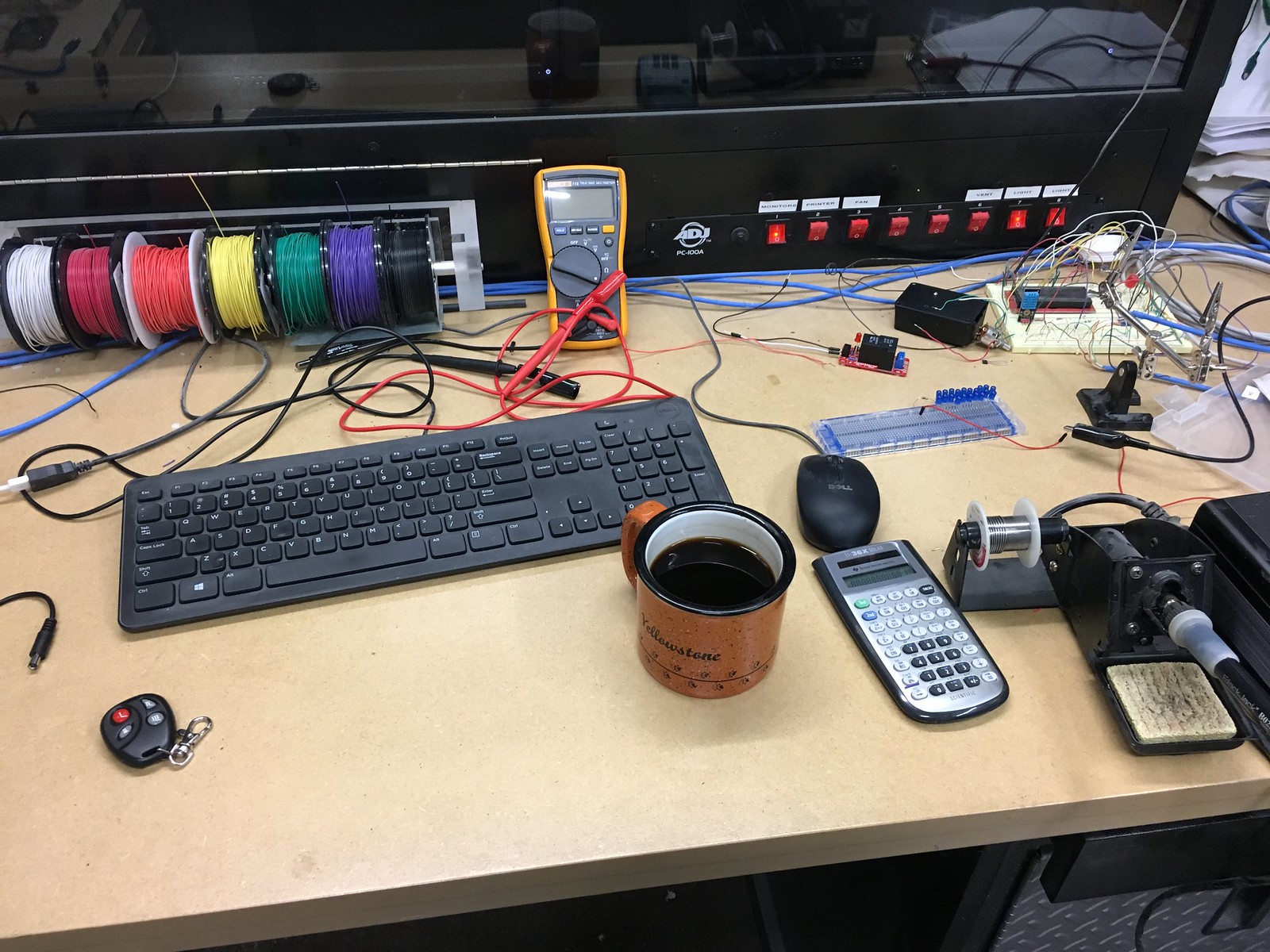

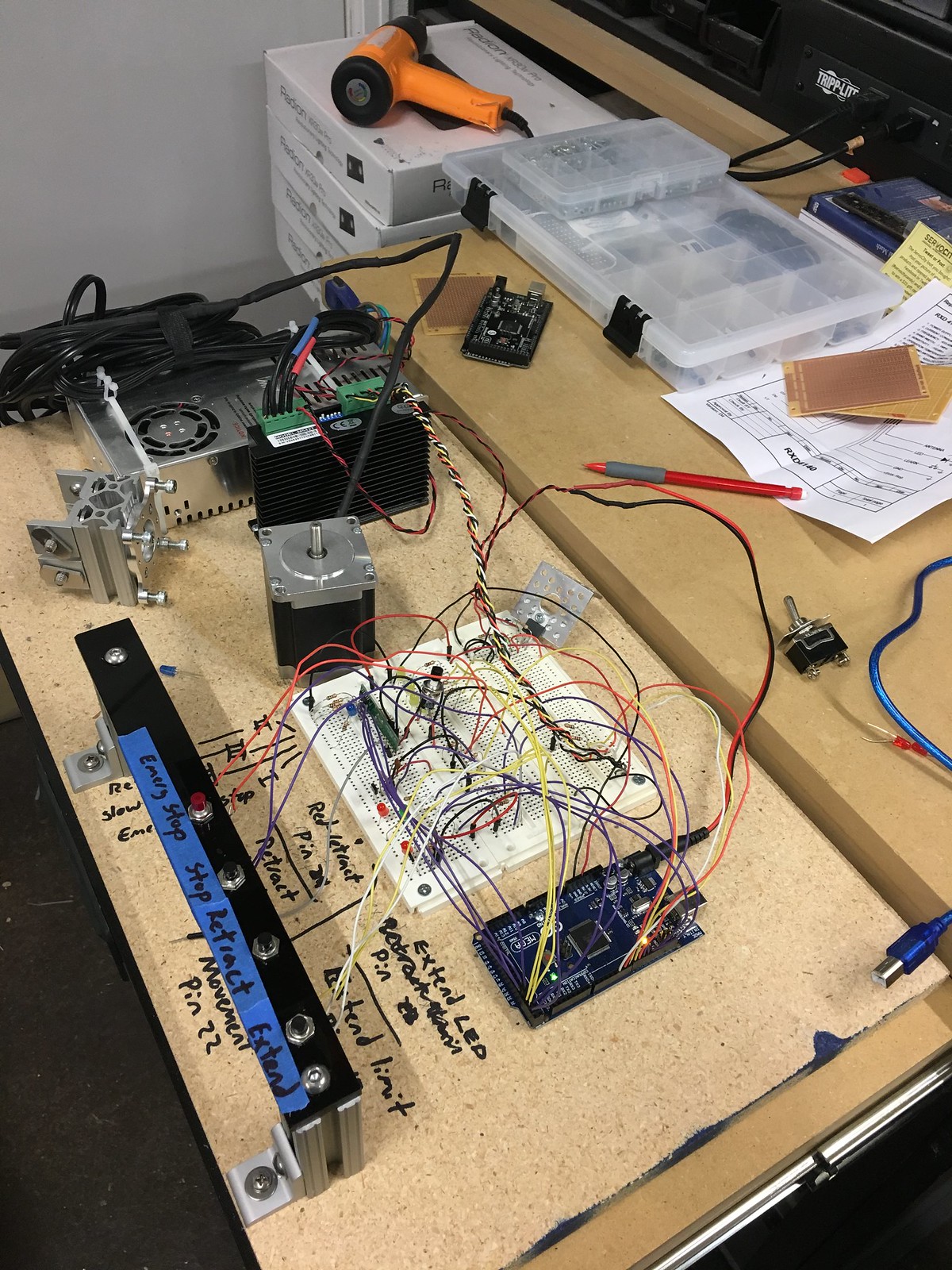

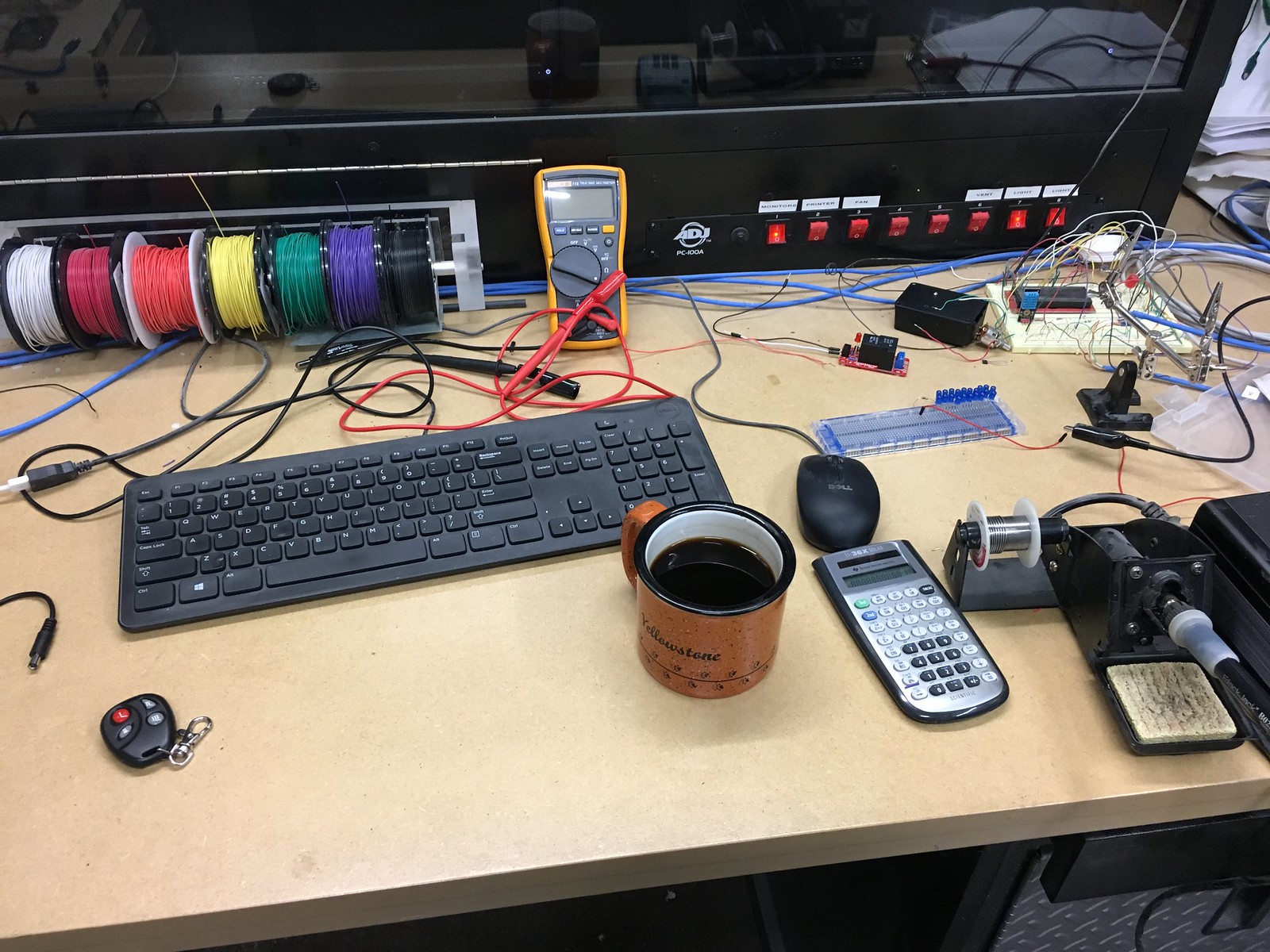

This month, I'm focused on prototyping and building the electronics that will control the hood movement. I'm using a stepper motor to maintain precise control of the rotation of the lead screw which also guarantees precise control of the hood's position at all times.

I'm prototyping everything on the bench first so that I can build out the software to integrate all of the switches and indicator LED's with the motor's movement. I will have physical buttons under the hood and a few other locations around the filtration room to open, close, pause, and emergency stop movement of the hood.

I'm also adding this remote control key fob that also duplicates the functionality of the physical buttons.

The next step is to mount everything on PCB's and install in the acrylic project box I built.

I'm prototyping everything on the bench first so that I can build out the software to integrate all of the switches and indicator LED's with the motor's movement. I will have physical buttons under the hood and a few other locations around the filtration room to open, close, pause, and emergency stop movement of the hood.

I'm also adding this remote control key fob that also duplicates the functionality of the physical buttons.

The next step is to mount everything on PCB's and install in the acrylic project box I built.

I've been thinking about this post for a few hours now, and I seriously can't wrap my head around this. I try to imagine myself doing something like this, and in my head EVERY time I press the key fob button either something is violently ejected or something catches fire. This my friend is complete awesomeness!

Thanks Chris and Kamran. I have 90% of everything assembled in the box. Tomorrow I will finish up the last of the soldering and plug it in. There's always the possibility of crossing wires during assembly so I'm hoping this doesn't turn into a ball of flames. It all worked during prototyping. I'm not too worried the 120 VAC side of this project is solid and I have it fused.

Assuming there are no flames, I'll mount the box and motor back up, plug everything in and start calibrating the system. If all goes well, I'll have a DIY garage door opener on my aquarium hood by tomorrow night! Pics and maybe video if all goes well. If you don't hear from me, all didn't go well. I'll accept mason jars of Zenia or Aptasia at my hospital bedside in place of flowers.

Assuming there are no flames, I'll mount the box and motor back up, plug everything in and start calibrating the system. If all goes well, I'll have a DIY garage door opener on my aquarium hood by tomorrow night! Pics and maybe video if all goes well. If you don't hear from me, all didn't go well. I'll accept mason jars of Zenia or Aptasia at my hospital bedside in place of flowers.

No balls of flames but something went wrong in the assembly process. The whole thing is acting glitchy so evidently I have a short somewhere. I can’t find it.

I get to strip it all apart back to the prototyping board. It’s not a complete loss. I have all of the buttons, switches, LEDs and terminals mounted inside of the case. That was a lot of work in itself and I can do a better job of wire management the second time around. I can reuse all of the I/O but I’ll have to test every single component.

So, minor setback of a few days work. It’s not a big deal but I’m am SOOO extremely ready to sit back and enjoy this tank without worrying about all of the unfinished goals.

I get to strip it all apart back to the prototyping board. It’s not a complete loss. I have all of the buttons, switches, LEDs and terminals mounted inside of the case. That was a lot of work in itself and I can do a better job of wire management the second time around. I can reuse all of the I/O but I’ll have to test every single component.

So, minor setback of a few days work. It’s not a big deal but I’m am SOOO extremely ready to sit back and enjoy this tank without worrying about all of the unfinished goals.

No balls of flames but something went wrong in the assembly process. The whole thing is acting glitchy so evidently I have a short somewhere. I can’t find it.

I get to strip it all apart back to the prototyping board. It’s not a complete loss. I have all of the buttons, switches, LEDs and terminals mounted inside of the case. That was a lot of work in itself and I can do a better job of wire management the second time around. I can reuse all of the I/O but I’ll have to test every single component.

So, minor setback of a few days work. It’s not a big deal but I’m am SOOO extremely ready to sit back and enjoy this tank without worrying about all of the unfinished goals.

I get to strip it all apart back to the prototyping board. It’s not a complete loss. I have all of the buttons, switches, LEDs and terminals mounted inside of the case. That was a lot of work in itself and I can do a better job of wire management the second time around. I can reuse all of the I/O but I’ll have to test every single component.

So, minor setback of a few days work. It’s not a big deal but I’m am SOOO extremely ready to sit back and enjoy this tank without worrying about all of the unfinished goals.

No balls of flames but something went wrong in the assembly process. The whole thing is acting glitchy so evidently I have a short somewhere. I can’t find it.

I get to strip it all apart back to the prototyping board. It’s not a complete loss. I have all of the buttons, switches, LEDs and terminals mounted inside of the case. That was a lot of work in itself and I can do a better job of wire management the second time around. I can reuse all of the I/O but I’ll have to test every single component.

So, minor setback of a few days work. It’s not a big deal but I’m am SOOO extremely ready to sit back and enjoy this tank without worrying about all of the unfinished goals.

I get to strip it all apart back to the prototyping board. It’s not a complete loss. I have all of the buttons, switches, LEDs and terminals mounted inside of the case. That was a lot of work in itself and I can do a better job of wire management the second time around. I can reuse all of the I/O but I’ll have to test every single component.

So, minor setback of a few days work. It’s not a big deal but I’m am SOOO extremely ready to sit back and enjoy this tank without worrying about all of the unfinished goals.

Your almost there bro! Set up is out of this world. You'll be kicking back soon enough, hope you have that meeting at your house you talked about! I've got some sweet sticks to put in that bad boy.

My refugium is coming to life and I am starting to see critters crawling around. I have some mangroves in there sending out fresh roots.

I even inherited a few free frags from a buddy who’s tank I’ve watched while he’s on vacation. Those are in QT right now.

I know the feeling on sitting back, hopefully I will finish painting the basement tonight which will just leave getting carpet installed and some minor finish work, then I can sit back and enjoy my tank. Well not really, then I can start on cleaning up the back portion of the tank that has been neglected for months, wire management and the sort.

The hood automation system is finally in place. I'll be using the remote control 99% of the time to open and close the hood. There are buttons on the main control unit but it's located near the ceiling. I added additional terminals on that unit so that some time in the future, I can run wires to buttons on the main "control station" if you could call it that. There will be a dedicated panel there as an interface for the hood movement. For now, I'll use the remote. Here are two vides:

I am so stupidly busy either finishing up one project, starting another, or cleaning up after myself with this build. The videos aren't that good. I did take better video but I don't have the time to edit them together, remove a bunch of background noise, and make it professional.

If anyone has any questions, let me know. For now, I'm finishing up a small acrylic project to hold all of my extra long reefing tools for the extra deep tank. Maybe next weekend I can start on the woodwork for the hood. What you see in the videos is 1/8" acrylic with the paper backing still on. I'm lining the inside of the hood with those as a moisture barrier.

I am so stupidly busy either finishing up one project, starting another, or cleaning up after myself with this build. The videos aren't that good. I did take better video but I don't have the time to edit them together, remove a bunch of background noise, and make it professional.

If anyone has any questions, let me know. For now, I'm finishing up a small acrylic project to hold all of my extra long reefing tools for the extra deep tank. Maybe next weekend I can start on the woodwork for the hood. What you see in the videos is 1/8" acrylic with the paper backing still on. I'm lining the inside of the hood with those as a moisture barrier.