Drew's 120 build

- Thread starter cdrewferd

- Start date

Look what's running.

Didn't have enough water to fill the fuge portion, but got everything else running. Gotta say though, the durso is stupid loud.

Does anybody know if it's supposed to have these holes?

You can see them towards the bottom of the pictured pipe. I can put a ball valve on the pipe if needed. It's a straight drop to the sump.

Didn't have enough water to fill the fuge portion, but got everything else running. Gotta say though, the durso is stupid loud.

Does anybody know if it's supposed to have these holes?

You can see them towards the bottom of the pictured pipe. I can put a ball valve on the pipe if needed. It's a straight drop to the sump.

I have. I spend 1.5 hrs last night trying to get it to run quiet. This is with the return pump on it's lowest setting. I do need to level the stand just a bit from side to side, hopefully that will help both overflows be used evenly.

The noiseis mainly the durso seeming to suck in a ton of air and then gurgling when it hits the sump. I tried slowing the flow, but didn't go too much as it just made the pump a bit louder.

The noiseis mainly the durso seeming to suck in a ton of air and then gurgling when it hits the sump. I tried slowing the flow, but didn't go too much as it just made the pump a bit louder.

Do you have a durso in each return or just in 1? If it's just in 1, what is going on in the other return?

Also do you have a hole drilled in the center/top of the durso cap?

From what you described (and if you don't have a hole drilled) it sounds like your durso is starting a siphon due to the waterline rising completely above the straight shot down to your sump, then the siphon gets broken when your waterflow line drops to the holes cut lower in your durso pipe. That's the rush then gurgling. If that is happening, you have too much flow.

Also do you have a hole drilled in the center/top of the durso cap?

From what you described (and if you don't have a hole drilled) it sounds like your durso is starting a siphon due to the waterline rising completely above the straight shot down to your sump, then the siphon gets broken when your waterflow line drops to the holes cut lower in your durso pipe. That's the rush then gurgling. If that is happening, you have too much flow.

1" durso in each overflow. Yes there is a hole in the top cap. If it's too much flow on the lowest setting, which should be somewhere around 700gph, then i'm going to have to change everything.

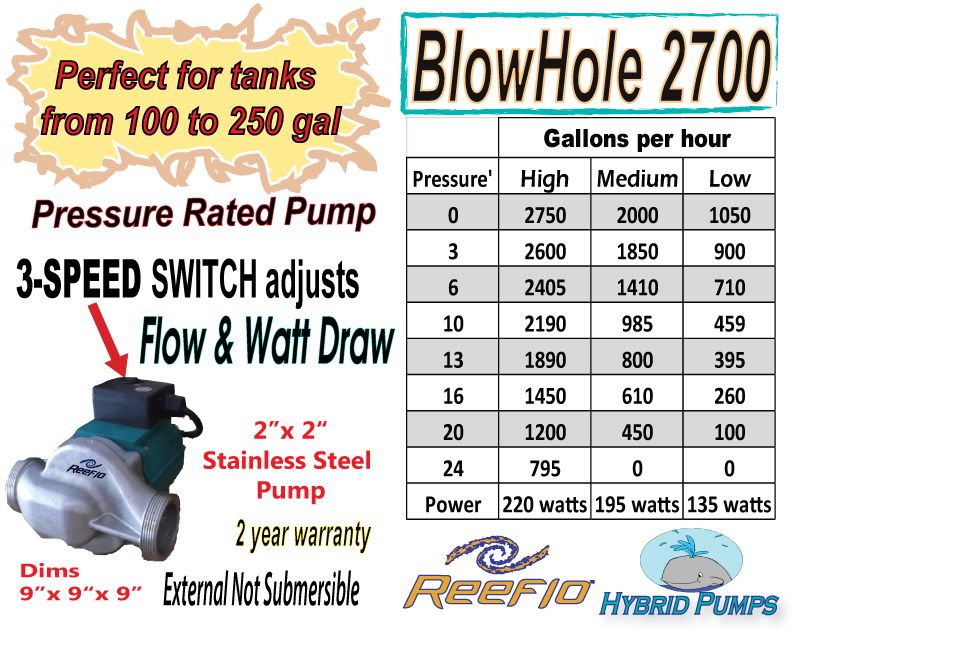

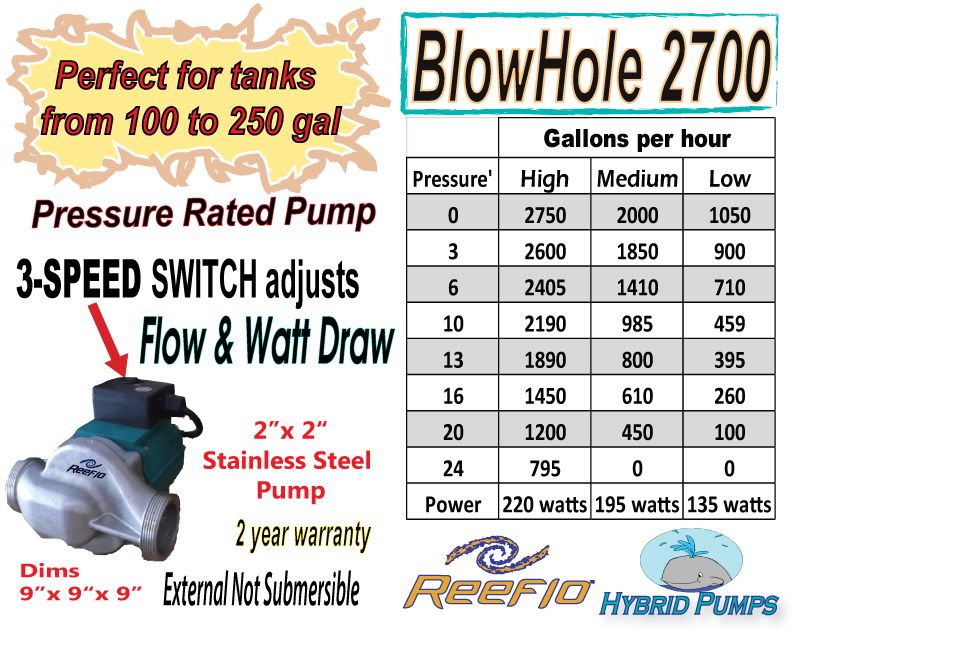

I'm using a Blow Hole 2700 pump. It's not out yet, I'm helping beta test it. So far it's awesome. Here's what it's rated at.

Like I said, it's on it's lowest setting and running only the return. Has 3 90's on it.

Would putting a ball valve and better balancing the dursos help? They have to be able to handle more than 700gph! The guy I bought the tank from had a Mag24 running wide open and it was nearly silent.

I'm using a Blow Hole 2700 pump. It's not out yet, I'm helping beta test it. So far it's awesome. Here's what it's rated at.

Like I said, it's on it's lowest setting and running only the return. Has 3 90's on it.

Would putting a ball valve and better balancing the dursos help? They have to be able to handle more than 700gph! The guy I bought the tank from had a Mag24 running wide open and it was nearly silent.

Hm. I've seen flow rate charts somewhere (maybe on WWM) that shows 1" bulkheads can really only average 350gph flow at max (without causing lots of siphoning), since you're right at that on your lowest pump setting and have some 90's (and maybe horizontal runs to the sump), it would seem it could be too much flow. But if it worked for the other guy...at about twice the flow rate (mag 24 is about 1400gph at 6')...then maybe that's not the issue. ???

It looks like your water line is right at the overflow teeth? I believe it needs to be below (most suggest 2") for the durso system to work right.

Some people cut a bigger air hole then put an airline with an air valve on it, to try to control air.

The dursos are unbalanced? Strange, this means one has a much lesser flow through than the other (a few 90's shouldn't make a difference). Did you reduce the pipe size on one and not the other? You may want to try ball valves on each line, to get them even. That may let you get back to much higher flow without one causing the other to siphon/gurgle back to a balanced level. Or you could do one durso and the other a full siphon drain with a ball valve? Like a herbie setup (picture link)? http://marine-engineers.org/2011/07/05/the-herbie-overflow/

Only other thought would be, if you're reducing at the bulkhead (like Chad pointed out), in theory you would have about 4x more flow capacity by rebuilding your dursos with 1/4" bigger PVC pipe.

EDIT: here's the flow through chart...bottom of this page in results/conclusion...http://www.wetwebmedia.com/BulkheadFloRateArt.htm

It looks like your water line is right at the overflow teeth? I believe it needs to be below (most suggest 2") for the durso system to work right.

Some people cut a bigger air hole then put an airline with an air valve on it, to try to control air.

The dursos are unbalanced? Strange, this means one has a much lesser flow through than the other (a few 90's shouldn't make a difference). Did you reduce the pipe size on one and not the other? You may want to try ball valves on each line, to get them even. That may let you get back to much higher flow without one causing the other to siphon/gurgle back to a balanced level. Or you could do one durso and the other a full siphon drain with a ball valve? Like a herbie setup (picture link)? http://marine-engineers.org/2011/07/05/the-herbie-overflow/

Only other thought would be, if you're reducing at the bulkhead (like Chad pointed out), in theory you would have about 4x more flow capacity by rebuilding your dursos with 1/4" bigger PVC pipe.

EDIT: here's the flow through chart...bottom of this page in results/conclusion...http://www.wetwebmedia.com/BulkheadFloRateArt.htm

hey brother i had a big issue with my durso in the triangle tank. I am forced count on a lot of my flow to come out of the returns in the tank and only had room for 2 1" drains. This tank sounded like a 747 coming down the runway in my living room. I started with putting a pin size whole in the top and progressively moving up in size every half an hour. TRUST ME. DON'T DO THIS. By the time i was done you could fit a golf ball down the top and it didn't fix any thing. I ended up doing exactly what dave said. I got some thick airline tubing (3/8" I believe) and put in a new whole on the top of my durso's. Make them about 6" so that you can play around with how high you need to place it. You should not need the valve on it, as this will constrict the flow to much and your pump will end up overflowing the main tank (thank god for a 12 with a great attention to detail or I would of had 3600 gph on the floor). Let me know if this works for you as well. Now the loudest item on my tank is the calc reactor dripping into the sump.

Sorry i thought for some reason you were looking for less flow. It may do that much but thats up there high enough id have to run the calculations cause im not sure for 2 1" pipes. Just curious why so much flow though the sump? For a 120 id think you would be just fine with half that and going with some sort of wavemaker/ powerhead to produce the rest of the flow in the tank. I am only putting 800 gph though mine per sanjay joshi's thought that moderate flow is better for efficient skimming/etc.

Ok so based on the bernoulli's principle:

Bernoilli's Equation v=sqrt(2gh)

Where:

v = Velocity

h = Height

g = Gravity

Flow Rate Equation Q= A x v

Where:

Q = Flow Rate

A = Cross Sectional Area

v = Velocity

If you have a standard 1" bulkhead that has an internal diameter of ~1" attached to a pipe of the same 1" diameter, and the pipe drops 2' to the sump, it "should" be capable of handling about 1,700 GPH of flow under full siphon which it would be

Assuming you have an addition 1' so say 3' from the top over the over flow pipe to where the water enter the sump the volume would be about 2040 GPH and you would still have the secondary pipe in the event that you needed more. i assume you are familiar with the "Herbie" method but if not its basically a "BeAnAnimal" without the third emergency pipe.

With your setup assuming just 2' of drop the Herbie over flow would be able to handle about 3000-3400 GPH for extreme situations and when tuned correctly should be almost silent. If you want to see how one works you can swing my my place again.

Bernoilli's Equation v=sqrt(2gh)

Where:

v = Velocity

h = Height

g = Gravity

Flow Rate Equation Q= A x v

Where:

Q = Flow Rate

A = Cross Sectional Area

v = Velocity

If you have a standard 1" bulkhead that has an internal diameter of ~1" attached to a pipe of the same 1" diameter, and the pipe drops 2' to the sump, it "should" be capable of handling about 1,700 GPH of flow under full siphon which it would be

Assuming you have an addition 1' so say 3' from the top over the over flow pipe to where the water enter the sump the volume would be about 2040 GPH and you would still have the secondary pipe in the event that you needed more. i assume you are familiar with the "Herbie" method but if not its basically a "BeAnAnimal" without the third emergency pipe.

With your setup assuming just 2' of drop the Herbie over flow would be able to handle about 3000-3400 GPH for extreme situations and when tuned correctly should be almost silent. If you want to see how one works you can swing my my place again.

Wow, great to know the real equation. Here's a chart I've been using for flows because I never knew the calculations (http://flexpvc.com/WaterFlowBasedOnPipeSize.shtml). Just curious, how do you adjust flow calculation for turns? Or is that way too complicated?

I have to put a post it note on my computer screen to avoid this.

Kalgra;205921 said:

Stop looking at my sack!

I have never see an equation or calculator which also accounts for turns. I'm sure that turns do play into it somewhat but probably not as much as when calculating head pressure so I think if the smallest pipe diameter for the drain is used and since gravity is a constant then its probably pretty negligible unless you just have a crazy number of turns or if the elevation is raising and dropping one or more times on the way to the sump.

I think this is a good rough estimate and for drew should work great. I have no idea how one would start factoring in a bunch of turns and other stuff.

By the way STOP LOOKING AT MY KITTIES JUNK!!

I think this is a good rough estimate and for drew should work great. I have no idea how one would start factoring in a bunch of turns and other stuff.

By the way STOP LOOKING AT MY KITTIES JUNK!!